5X Line Truly flexible

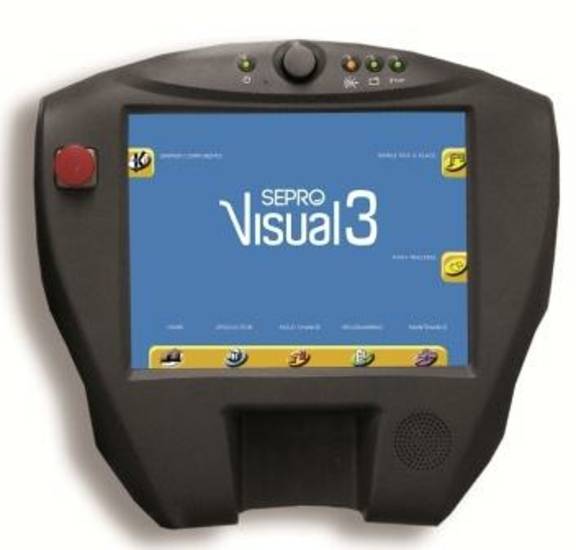

5X Line robots are designed from latest generation fast and precise Sepro 3-axis Cartesian robots with a Sepro 2-axis servo wrist. A unique combination that provides a number of solutions for automating injection molding machines. These robots installed on the IMM can be used for unloading and processing parts; they can be located at the end of the IMM to perform post-processing. They can be programmed quickly and efficiently thanks to the power and user friendliness of the Visual 3 control system.

Download the brochure

Presentation

The assurance of high performance and simplicity!

5X Line associated with the power of Visual 3: A perfect solution for the most complex Automation systems with up to 16 axes.

Overview

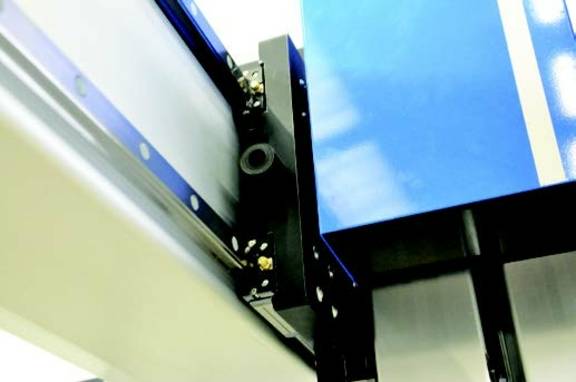

- Structural frame for increased rigidity

- Prismatic linear guides for high accelerations

- Powerful servomotors and antivibration software

- Path tracking function standard thanks to Visual 3

- Direct or telescopic (except for 5X-15) vertical arm

- Heavy Load Version (Option) on 5X-35 for carrying loads up to 20 kg

Good-looking mechanics!

5X line is a range of high-performance and flexible 5-axes industrial robots. It can be adapted to all your unloading and injected part completion applications.

The range comprises 3 models, the 5X-15, the 5X-25 and the 5X-35, to equip your IMMs ranging from 30 to 800 tons.

Rigid

The structural frame and prismatic guide rails ensure greater rigidity, adapted to the high acceleration of moving parts.

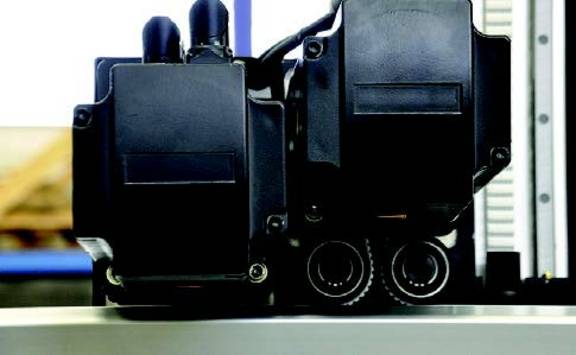

Powerful servomotors and antivibration software

Powerful servomotors associated with intelligent and anti-vibration software guarantee maximum acceleration and minimum mold intervention time.

Y Free Function

A historical standard on all of Sepro’s Cartesian robots: it simplifies the programming of part accompaniment during ejection and can reduce the cost of your EOATs by simplifying their design.

The assurance of a Sepro servo wrist

The Sepro 2-axes, compact servo rotations guarantee high precision, high speeds and can be easily adapted to even the most elaborate applications: insert placing, complex extraction paths in the mold, path tracking for flame treatment.

Control systems

Specifications

Applications

- Complex universal unloading applications for ejected parts

- Post processing of parts

- Simple Pick & Place

- Simple stacking applications

- Complex applications: stacking, advanced palletizing, insert placing, insert molding, vision

- Path tracking

- Applications requiring multiple part orientations in space

- Network communication with peripherals

You may also be interested in:

Technology 5 Dual Arm

Premium IML : In-Mold-Labelling system

Technology S7 Line

Premium 7X Line

Premium 6X Visual: Sepro - Yaskawa

Contact our sales team

All fields are required

How can we help you?

The information collected by SEPRO ROBOTIQUE is processed electronically in order to set up commercial relations between you and SEPRO ROBOTIQUE's Sales Department. Data points collected via this form are required except those marked as optional. Data recipient is SEPRO ROBOTIQUE's Sales Department, the data controller. Your data will be kept for the time necessary to process your requests. Pursuant to the French Data Protection Act of 6 January 1978, as amended, and the GDPR, you have the right to access, query, limit, transfer, modify, correct, and erase your personal data. You may also object at any time to the processing of your personal data. You can exercise these rights by sending us an e-mail to the following address: dataprotection@sepro-group.com or by writing to SEPRO ROBOTIQUE SAS, Henry Bessemer Street, ZI Acti-Est, CS 10084, 85003 La Roche Sur Yon, and including a copy of their signed identity document.